MP Materials SPAC Presentation Deck

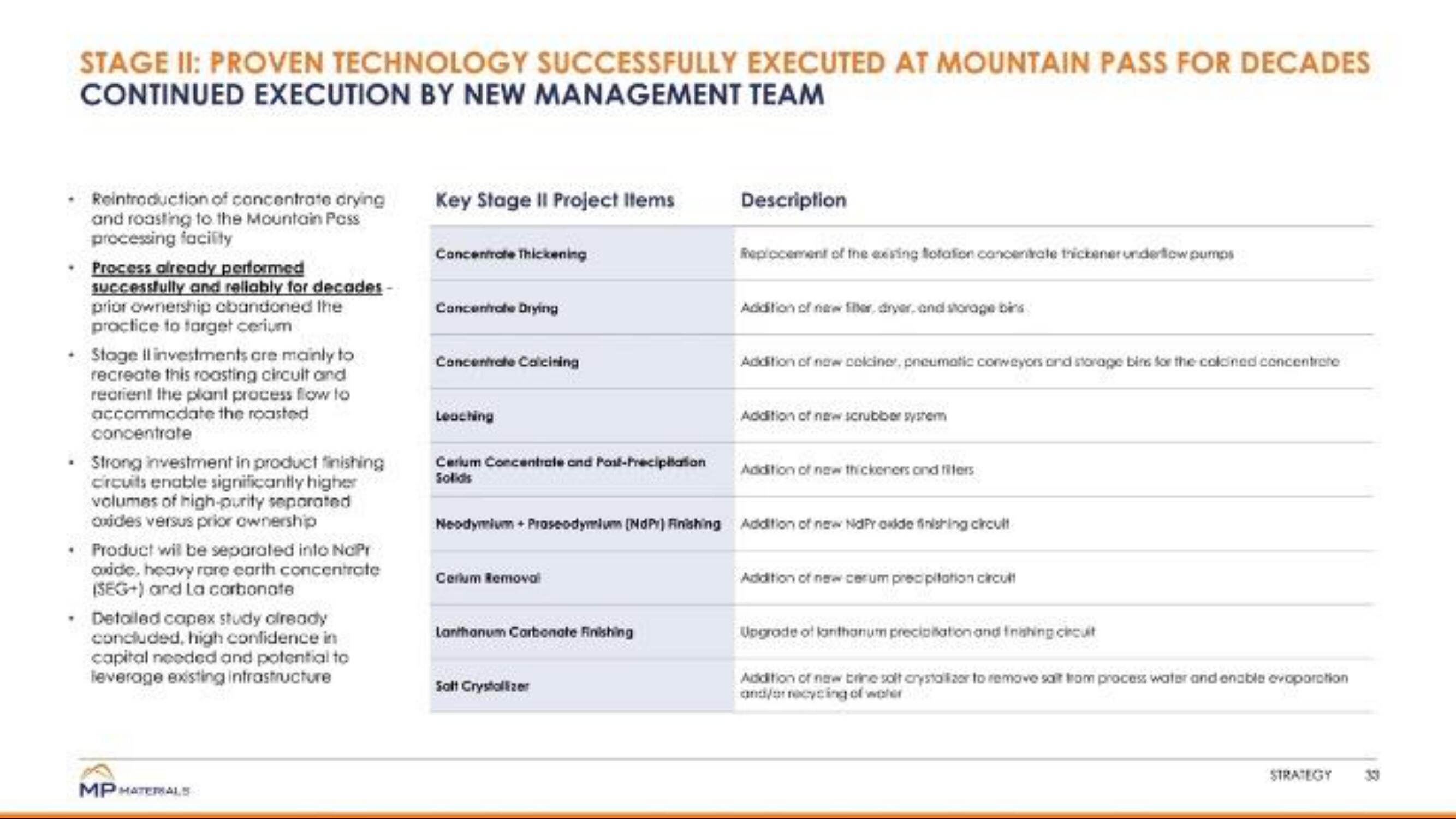

STAGE II: PROVEN TECHNOLOGY SUCCESSFULLY EXECUTED AT MOUNTAIN PASS FOR DECADES

CONTINUED EXECUTION BY NEW MANAGEMENT TEAM

Reintroduction of concentrate drying

and roasting to the Mountain Pass

processing facility

• Process already performed

successfully and reliably for decades-

prior ownership obandoned the

practice to target cerium

Stage Il investments are mainly to

recreate this roasting circuit and

reorient the plant process flow to

accommodate the roasted

concentrate

Strong investment in product finishing

circuits enable significantly higher

volumes of high-purity separated

oxides versus prior ownership

Product will be separated into NcPr

oxide, heavy rare earth concentrate

(SEG+) and La carbonate

• Detailed capex study already

concluded, high confidence in

capital needed and potential to

leverage existing infrastructure

MPMATERALS

Key Stage II Project Items

Concentrate Thickening

Concentrate Drying

Concentrate Calcining

Leaching

Cerium Concentrate and Post-Precipitation

Solids

Cerium Removal

Lanthanum Carbonate Finishing

Description

Soft Crystalizer

Replacement of the existing flotation concentrate thickener undertow pumps

Addition of new filer, dryer, and storage bins

Addition of new colciner, pneumatic conveyors and storage bins for the colcined concentrate

Neodymium + Praseodymium (NdPr) Finishing Addition of new NdProxide finishing circult

Addition of new scrubber system

Addition of new thickeners and filters

Addition of new cerum precipitation circuit

Upgrade of lanthanum precipitation and finishing circuit

Addition of new brine soft crystallizer to remove saft from process water and enable evaporation

and/or recycling of water

STRATEGY 33View entire presentation