Arrival SPAC Presentation Deck

ARRIVAL'S NEW METHOD

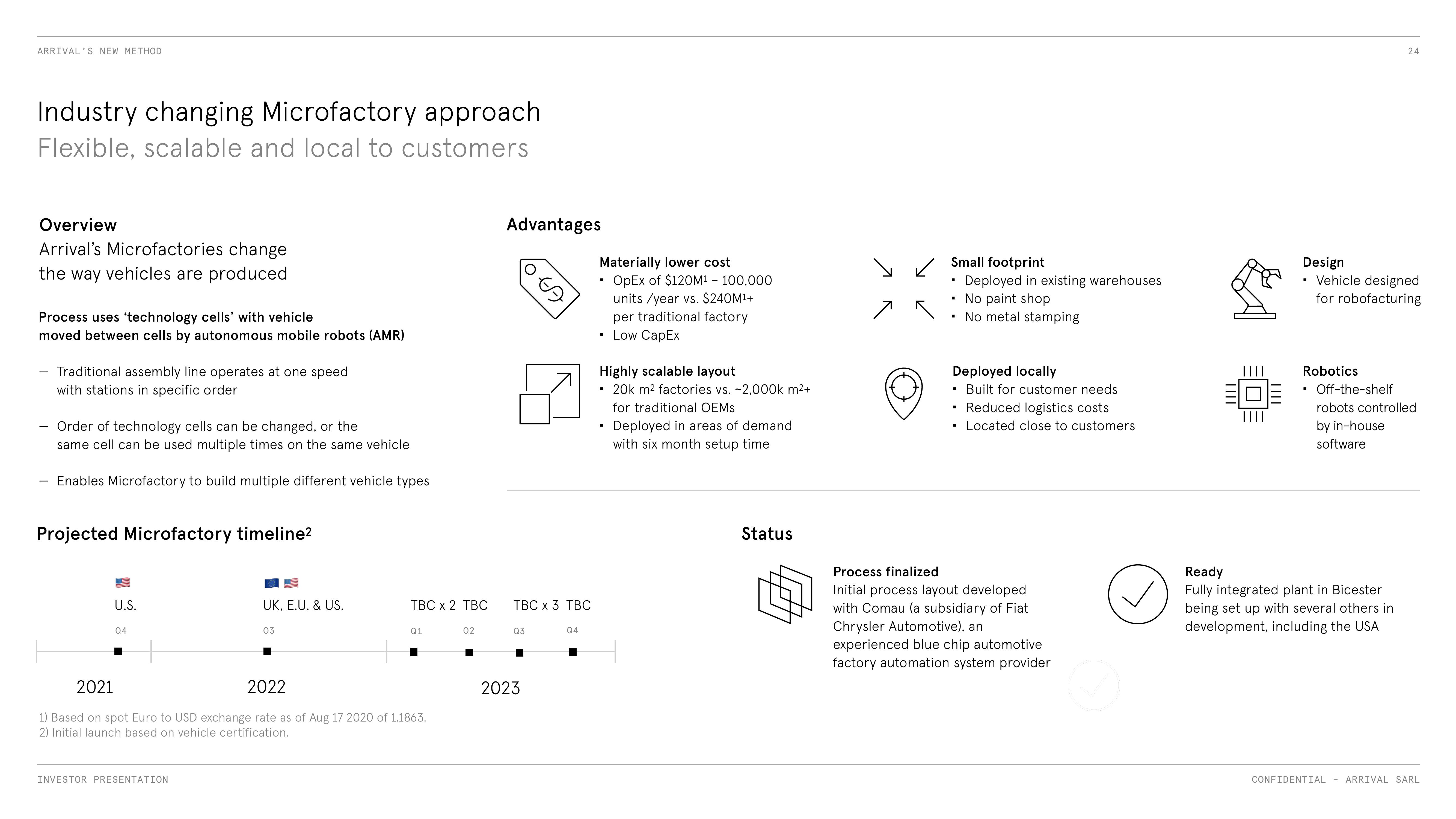

Industry changing Microfactory approach.

Flexible, scalable and local to customers

Overview

Arrival's Microfactories change

the way vehicles are produced

Process uses 'technology cells' with vehicle

moved between cells by autonomous mobile robots (AMR)

- Traditional assembly line operates at one speed

with stations in specific order

- Order of technology cells can be changed, or the

same cell can be used multiple times on the same vehicle

- Enables Microfactory to build multiple different vehicle types

Projected Microfactory timeline²

U.S.

Q4

UK, E.U. & US.

INVESTOR PRESENTATION

Q3

TBC x 2 TBC

Q1

2021

2022

1) Based on spot Euro to USD exchange rate as of Aug 17 2020 of 1.1863.

2) Initial launch based on vehicle certification.

Q2

Advantages

4

TBC x 3 TBC

Q3

2023

Q4

■

Materially lower cost

• OpEx of $120M¹ 100,000

units/year vs. $240M¹+

.

Highly scalable layout

20k m² factories vs. -2,000k m²+

for traditional OEMs

.

per traditional factory.

Low CapEx

.

Deployed in areas of demand

with six month setup time

Status

✓ Small footprint

як

• Deployed in existing warehouses

No paint shop

No metal stamping

Deployed locally

• Built for customer needs

Reduced logistics costs

. Located close to customers

Process finalized

Initial process layout developed

with Comau (a subsidiary of Fiat

Chrysler Automotive), an

experienced blue chip automotive

factory automation system provider

||||

||||

Design

• Vehicle designed

for robofacturing

Robotics

24

Off-the-shelf

robots controlled

by in-house

software

Ready

Fully integrated plant in Bicester

being set up with several others in

development, including the USA

CONFIDENTIAL - ARRIVAL SARLView entire presentation